An ISO Certified Company

- GST No.: 27ATMPN1987A1ZH

- +91-8554949014

- info@suyashindustriespune.com

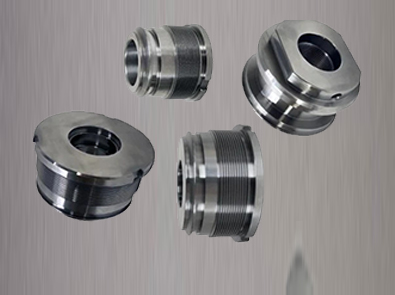

VMC Machine Components

VMC (Vertical Machining Center) machine components are essential parts of a vertical machining center, which is used for cutting, drilling, and shaping materials like metal, plastic, and wood. VMCs are widely used in manufacturing due to their precision and versatility. Below are the key components of a VMC machine:

Programing Software for CNC Machine

WorkNC is a CNC software that has many features, including:

- Automatic detection and management : WorkNC can automatically detect and manage geometry and machining zones.

- Toolpaths : WorkNC can design toolpaths for high-speed machining.

- Collision detection : WorkNC can detect collisions and automatically update stock.

- Machining simulation : WorkNC can simulate machining.

- Tool and tool holder library : WorkNC has a library of tools and tool holders.

- Batch mode calculations : WorkNC can perform calculations in batch mode.

- Postprocessor generator : WorkNC can generate postprocessors.

- Advanced parallel processing : WorkNC can calculate up to four toolpaths simultaneously in each work zone.

- Automatic drilling module : WorkNC has an automatic drilling module that uses pre-drilling, tapping, and chamfering data.

- Automatic feature detection and recognition : WorkNC has an automatic function that can recognize cavities and detect insertion axes.

- Machine and tool holder collision checking : WorkNC can check for collisions between machines and tool holders.

By using WorkNC software, we are able to design the best component.

AGNI+V4

| Specification | Details |

|---|---|

| Table Size | 900 x 450 mm |

| Axis Travel (X, Y, Z) | 600 x 450 x 500 mm |

| Spindle Speed | 8000 RPM |

| Position Accuracy | +/- 0.003 mm |

| Repeatability Accuracy | +/- 0.003 mm |

| Controller | FANUC |

CHAKRA+V6

| Specification | Details |

|---|---|

| Table Size | 1200 x 600 mm |

| Axis Travel (X, Y, Z) | 1050 X 610 X 610 mm |

| Spindle Speed | 6000 RPM |

| Position Accuracy | +/- 0.003 mm |

| Repeatability Accuracy | +/- 0.003 mm |

| Controller | FANUC |